ABEX ROCK BREAKERS

ENGINEERED PERFECTION

- ABEX Rock Breakers are available for carrier machines from 1.5 ton to 80 ton, and the factory will build larger to order. ABEX design principles are based on quality, durability, and performance. ABEX Tech Co (South Korea) have been manufacturing rock breaker components for global brands for over 40 years, and have been producing their own brand since 2005.

- Korean hydraulic manufacturing technology and quality is globally recognised as being of the highest quality and yet available at unprecedented value. This is why many rock breaker brands from around the world (including USA, Canada, Japan, Europe, and UK) source their breaker components from South Korea.

- There are over 140 ABEX Breakers operating in New Zealand, from smaller units doing concrete work, right up to heavy duty quarry applications. There are over 20 units working in the Pacific Islands.

- The ABEX Breakers are supported by parts and technical support within New Zealand.

- The common feedback we have from our clients is the ABEX Breakers have a high impact force, with less impact coming back through the machine, when compared to other brands of breakers they have used. A key contributing factor for this is the ABEX patented buffer system, which is designed to reduce recoil forces to the carrier machine, and at the same time channelling the recoil energy back down the chisel. ABEX Breakers have other unique features; - Autogreaser on 12 ton and up, significantly increasing chisel, thrust ring, and thrust bush life (main wear items)

- - Impact frequency varies according to load / material density

- - Breaker will not fire without load on the chisel, protecting internal components from blank firing - Long thrust bush holds the chisel in true alignment, resulting in longer wear life for both the chisel and the bushes

- - Thrust bush is replaceable externally - no need to disassemble breaker body, reducing cost and risk of contamination

- - Patented buffer system, that not only protects the carrier machine from impact forces, but redirects this energy back down the chisel, dramatically increasing impact forces to the work tool

- -12 Months parts warranty

SCROLL TO BOTTOM OF PAGE FOR SERVICE VIDEOS

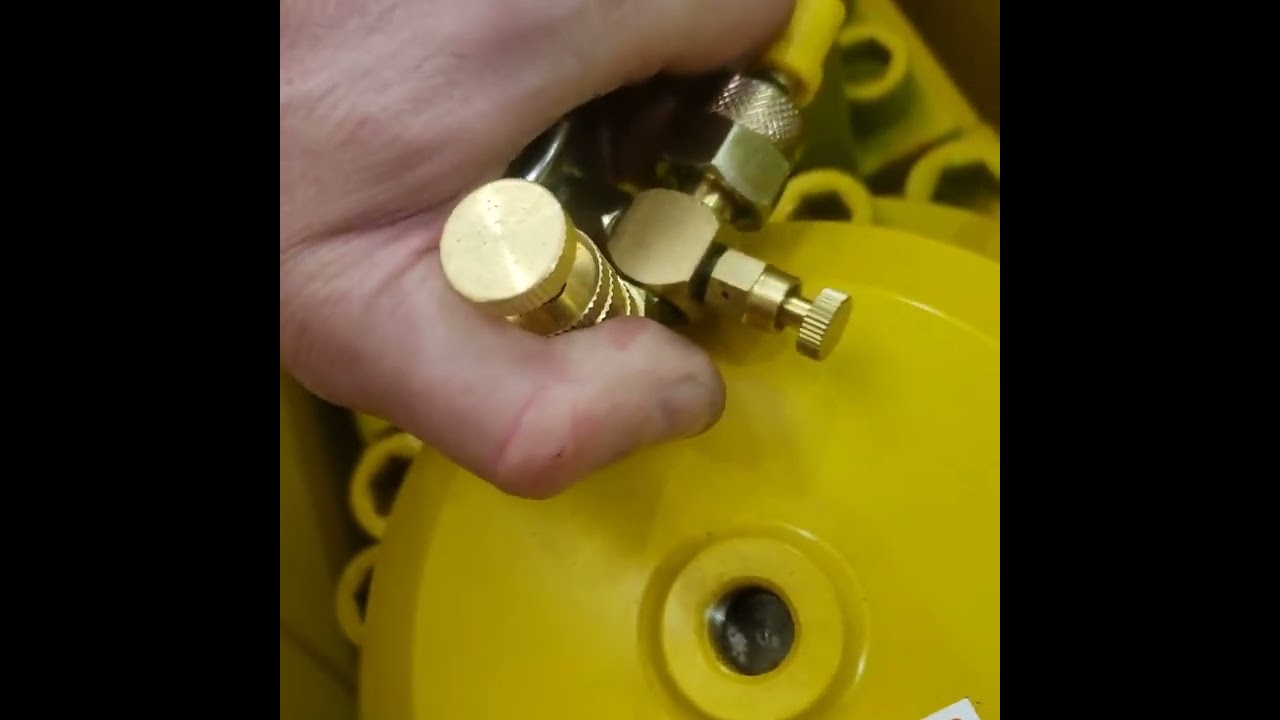

CHARGING THE BACK-HEAD

CHARGING THE ACCUMULATOR

CHISEL FITMENT

ABEX EXB110SN Breaker on Doosan DX340LC breaking Greywacke, Mangawhai

Video can’t be displayed

ABEX EXB110SN Breaker on Cat 330FL, Waikato

Video can’t be displayed

ABEX EXB70SN Breaker on Cat 323FL, Auckland

Video can’t be displayed

ABEX EXB60SN Breaker working solid basalt, Auckland

Video can’t be displayed

ABEX EXB40SN Breaker on Doosan DX140LCR, CRL Project, Auckland

Video can’t be displayed

EXB20SN Breaker on Cat 308NG, CRL Project, Auckland

Video can’t be displayed

SERVICE VIDEOS

Video can’t be displayed

Preparing to charge the back-head

Video can’t be displayed

Charging the Accumulator - EXB70 and above

(the smaller breakers do not have an accumulator)

Video can’t be displayed

Charging the back-head

Video can’t be displayed

Fitting a chisel

(EXB8SN / EXB10SN / EXB20SN)

CONTACT

James Maunsell - Managing Director

Mobile: +64 27 345 3318

Email: digmax@digmax.com

25 Smales Road, East Tamaki

Auckland 2013

Warehouse entry: 91 Lady Ruby Drive

- drive down lane past Custom Utes, top warehouse

(viewing by appointment)